Shoppers mix them up, then face peeling sofas and costly returns. Know the facts, and you will choose once and keep your budget safe.

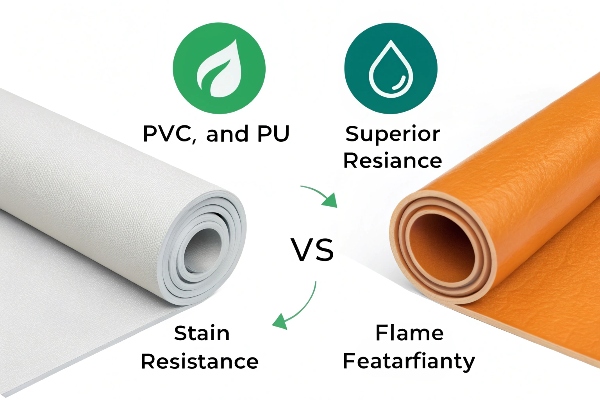

PU leather is softer, more breathable, and made with a polyurethane coating. PVC leather is stiffer, less porous, and coated with polyvinyl chloride plus plasticizers. Their base fabrics can be the same.

Many buyers quit reading after bullet lists. Stay with me, and I will break down feel, durability, cost, and sustainability from my own sourcing floor stories. Your next order will be smarter—promise.

Which Is Better, PU Leather or PVC Leather?

You want a clear winner, yet every catalog note feels like marketing fluff. The wrong pick may doom a car seat or a stylish bag before launch.

The “better” choice depends on touch, breathability, price, and the end-use. PU wins for comfort and eco goals; PVC wins for rugged, low-maintenance surfaces.

Dive deeper

I test rolls every month in our lab, then I sit on prototypes in my own living room. The decision matrix below is what I share with clients:

| Factor | PU Leather | PVC Leather |

|---|---|---|

| Hand feel | Soft, warm, closer to natural hide | Firm, sometimes plastic-like |

| Breathability | Good | Low |

| Abrasion resistance | Moderate to high (depends on topcoat) | High |

| Chemical resistance | Fair | Excellent |

| Price range | $$ | $ |

| Eco perception | Better (solvent-free PU, bio-based options) | Weaker (chlorine content, phthalate worries) |

I guide furniture makers toward PU for lounge chairs because customers sit for hours. I push PVC for medical recliners that must shrug off disinfectants. When margin is tight, hybrid “PU/PVC” laminates can split the difference: PVC base for strength, thin PU top for hand feel. Testing each grade under real temperature and humidity always seals the final call.

Is PVC Better Than PU?

Factories promise “PVC is stronger,” while design blogs scream “PU is greener.” You are stuck in the middle, fearing stock that will not move.

PVC outperforms PU in chemical, stain, and flame resistance, yet it lags in softness, breathability, and eco image. “Better” is task-specific, not absolute.

Dive deeper

On a recent automotive project for the Middle East, my client needed dashboards that resist 60 °C heat and sunscreen spills. We ran both materials through tests:

- Heat aging at 120 °C for 200 h

- UV exposure of 1 000 h

- Sunblock stain test

PU cracked at 190 h and showed yellowing under UV. PVC passed. For the same dashboard we still used PU in colder European models, where a softer touch ranked higher than solvent resistance.

Key trade-off list

- Durability: PVC gains

- Comfort: PU gains

- Weight: PU usually lighter by 10-15 %

- Odor: PU milder; PVC may off-gas if low-grade

- Fire codes: PVC often meets FMVSS 302 without extra back-coat; PU needs additives

When I map these points on a whiteboard with clients, the “better” label fades. The right material flows from the user story, not marketing hype.

Is PVC Leather Good Quality?

You may picture cheap shiny boots from street stalls. Yet car interiors and hospital beds use PVC daily. The label “PVC” alone does not set quality.

High-grade PVC leather delivers 100 000+ Martindale rubs, medical-grade stain resistance, and consistent color. Quality depends on resin, plasticizer, and top coat design.

Dive deeper

Quality starts with the recipe. I visit compounding rooms where technicians tweak:

- PVC resin K-value (molecular weight)

- Phthalate-free or phthalate plasticizers

- Heat stabilizers—calcium zinc rather than heavy metals

- Topcoat: urethane lacquers, silicone hybrids

A cheap market PVC uses high-VOC plasticizers that migrate; the surface gets tacky in months. Our premium grade for bus seats adds a cross-linked PU topcoat. It survived 250 000 double rubs and bleach wipes without haze.

Below is my quick audit sheet for buyers:

| Checklist Item | Pass Mark |

|---|---|

| Base fabric weight | ≥200 g/m² polyester or better |

| PVC coating thickness | 0.4–0.6 mm for furniture |

| Plasticizer migration test | ≤2 % weight loss at 70 °C/24 h |

| VOC emission | ≤120 µg/m³ after 24 h |

| Color fastness to light | ≥4 Gray scale |

Ask your supplier for every sheet; lab tests do not lie. Quality PVC can outlast bargain PU many times over.

What Is the Disadvantage of PU Leather?

Glossy catalogs praise PU as “vegan,” but few mention its weak spots. Missing these could spark warranty claims and hurt your brand.

PU leather can scratch, hydrolyze in humid heat, and cost more than PVC. It also needs tighter process control to stay solvent-free and odorless.

Dive deeper

My own sofa story explains it best. I picked a budget PU, confident in my vendor. Two summers in subtropical Shenzhen later, the surface flaked. Here is why:

- Hydrolysis: Moisture attacks ester bonds in the PU top layer.

- UV: Sunlight speeds up bond breakage.

- Poor topcoat: Low solid content could not block humidity.

When we develop PU now, I insist on:

- Ether-based PU systems for higher hydrolysis resistance

- Minimum 1.5 g/L anti-UV agent

- Final humidity-and-heat cycle test: 70 °C / 95 % RH for 168 h

Extra cost? About 0.30 USD per meter, still cheaper than field failures. Clients accept this once I show the flake photos. Below is a quick risk table.

| Risk | PVC Equivalent Issue | PU Disadvantage Level |

|---|---|---|

| Hydrolysis | Rare | High |

| Scratch sensitivity | Moderate | Higher |

| Stain resistance | Strong | Moderate |

| Eco score | Lower | Higher |

| Price | Low | Mid to high |

No material is perfect. My job is to highlight limits before they hit your customer reviews.

Conclusion

PU feels better and can be greener; PVC fights stains and fire better. Match material to end-use, run lab tests, and you will ship products with confidence.