The gap between single-layer and multi-layer perforated microfiber often confuses buyers because both look similar at first glance, yet they perform very differently.

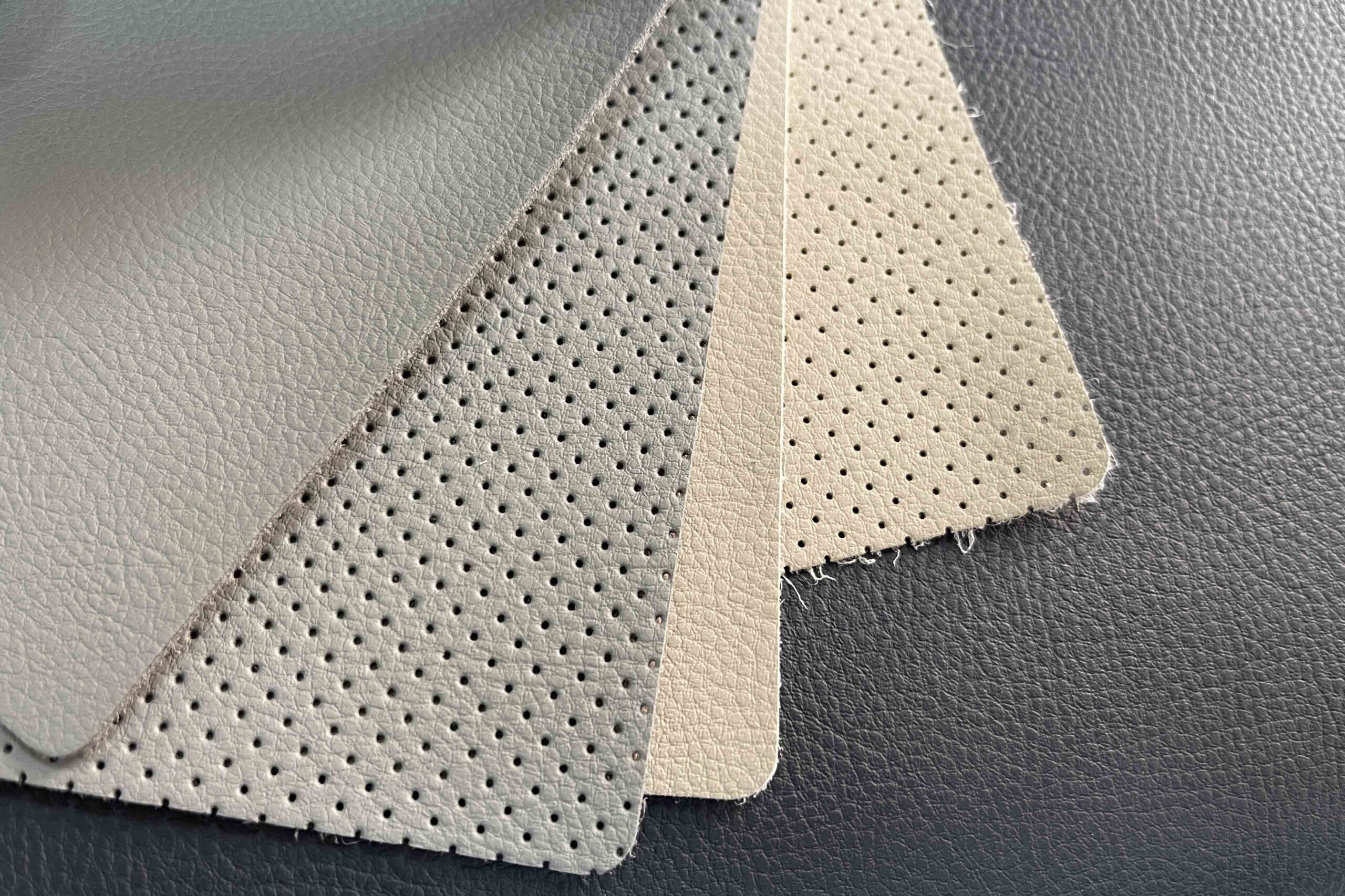

Single-layer perforation creates clean and even holes, while multi-layer perforation produces mixed hole sizes. The choice depends on breathability needs, cost targets, and surface consistency.

Many clients ask me which type they should choose, and I always tell them that the answer depends on what they want to achieve in comfort, appearance, and budget.

The Complete Process of Microfiber Perforation: From Material Selection to Final Quality Inspection?

Every perforation project starts with material choices, and small decisions at this stage change the final performance.

Single-layer perforation uses one uniform microfiber sheet, so the holes remain even and stable. Multi-layer perforation stacks two or more sheets, so the needle passes through uneven layers and creates mixed hole sizes.

When I walk clients through the perforation line in our partner factories, I see how each step affects the final feel. The process starts with microfiber base selection. I usually look at fiber density, backing strength, and coating softness. These factors decide whether the perforation machine can punch clean holes.

After that, we choose between needle-die perforation, laser perforation, or rotary punch. For single-layer material, all methods create smooth holes. For multi-layer sheets, needle-die works better because laser heat spreads across uneven layers and sometimes causes distortion. I always warn buyers that multi-layer perforation will not give perfect uniformity, even with the best equipment.

Then we set hole diameter and pattern alignment. Single-layer sheets allow precise hole spacing. Multi-layer materials shift slightly during punching, so the pattern becomes less aligned. This is normal and accepted in many applications where price matters more than perfection.

In the last step, we inspect hole size consistency, tear resistance, color stability, and softness. I often test breathability myself by holding a sheet close and feeling airflow. The difference between single and multi-layer becomes obvious at this moment. Single-layer sheets breathe more evenly. Multi-layer sheets allow airflow but not in a perfectly balanced way.

| Step | Single-Layer Result | Multi-Layer Result |

|---|---|---|

| Material stability | Very stable | Slight layer shift |

| Hole uniformity | Clean and even | Mixed hole sizes |

| Pattern alignment | Accurate | Less aligned |

| Breathability | Smooth airflow | Uneven airflow |

| Cost | Slightly higher | More cost-effective |

How Different Perforation Methods Affect Microfiber Breathability and Comfort: A Comparison of Hole Types, Density, and Softness?

Breathability depends on hole type and density, and each method changes the comfort level.

Large holes improve airflow but reduce strength. Small holes keep the surface smooth. Higher density gives better air movement but lowers coating durability.

When clients visit our showroom, I let them compare different perforation methods by hand. Needle-die perforation makes round holes with soft edges. Laser perforation creates sharp and crisp holes but can stiffen the coating. Rotary perforation creates long oval holes, which increase airflow but change the surface texture.

Hole density also matters. When the density is high, moisture escapes faster, making footwear linings more comfortable. But density also reduces the coating support. I often guide customers to choose moderate density for car interiors and higher density for sports shoes.

Softness changes as the coating loses support during perforation. Single-layer materials soften in a natural way. Multi-layer materials soften in an uneven way because different layers react differently after punching. Some areas stay firm while others stretch more.

Here is how perforation factors affect feel:

| Factor | Effect on Breathability | Effect on Comfort |

|---|---|---|

| Hole size | Larger = higher airflow | Too large may feel rough |

| Hole density | Higher = better ventilation | Too high reduces strength |

| Perforation type | Laser = sharp edges | Needle = softer feel |

| Layer structure | Single-layer = even breathing | Multi-layer = mixed softness |

Emerging Applications of Perforated Microfiber: Innovations in Footwear, Automotive Interiors, Electronics, and More?

New industries now use perforated microfiber because it gives lightweight breathability and stable shape.

More brands choose perforated microfiber for shoes, seats, dashboards, cases, and even wearable electronics.

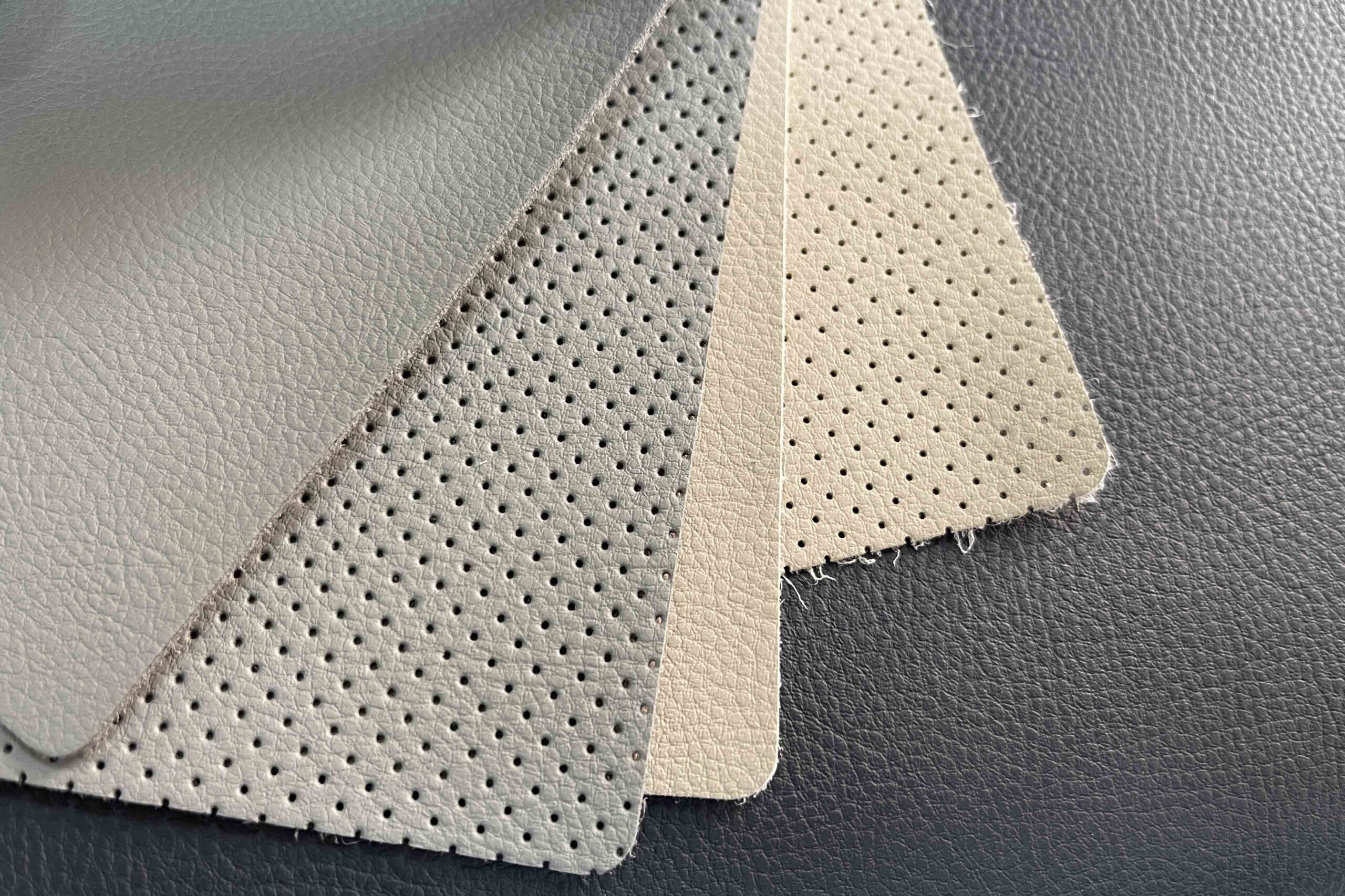

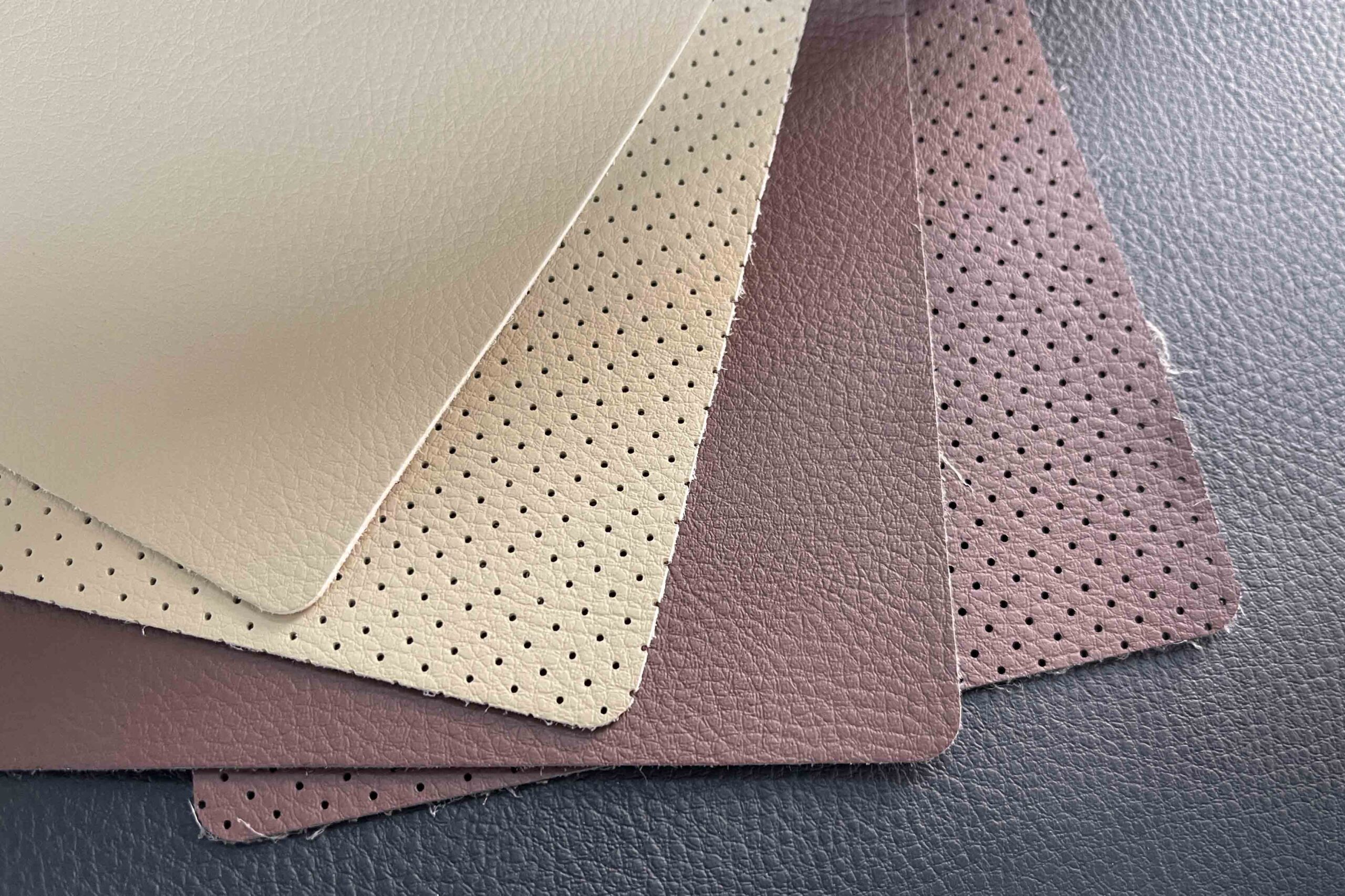

In recent years, I helped several clients develop new products that required controlled airflow and a clean visual pattern. Footwear brands ask for high-density micro-holes to increase sweat release. Car interior clients want small, uniform holes for premium seat designs, and this is where single-layer perforation becomes important. They do not want uneven holes because it affects the luxury look.

Electronics makers ask for perforated microfiber for speaker covers and device sleeves because the airflow helps sound transmission and heat release. Multi-layer perforation works in these cases because cost is more important than visual perfection.

Fashion brands use perforated microfiber to create lightweight bags with special textures. They like multi-layer perforation because the irregular hole size gives a handmade look. Sports equipment brands use perforated microfiber for gloves, pads, and protective covers to reduce moisture buildup.

Below is a simple overview of industries and the best perforation choice:

| Industry | Best Perforation Type | Reason |

|---|---|---|

| Footwear | Single or multi, high density | Strong breathability |

| Automotive | Single-layer | Clean, even appearance |

| Electronics | Multi-layer | Balanced cost and airflow |

| Bags & accessories | Multi-layer | Creative texture |

| Furniture | Single-layer | Uniform look and stable performance |

Conclusion

Single-layer gives clean holes and stable airflow. Multi-layer offers value and flexible use across industries.