You want leather’s look without its cost. Your client also asks for a one-of-a-kind print and extra cushion. Real hide cannot meet every wish, yet delays keep piling up.

Custom printed faux leather bonded with foam solves price, pattern, and comfort in one roll. It combines a printable PU face, soft backing, and ready-to-sew thickness, so you save time and money on upholstery jobs.

Projects stall when choices feel endless. Keep reading and I will show how this layered material compares with bonded leather, how long each lasts, what print methods work, and what trade-offs you must expect. My ten years in synthetic leather sourcing will guide every point.

Which is better faux leather or bonded leather?

You pick between two low-cost options, yet both promise the same leather look. Your risk is choosing the wrong one and re-ordering stock later.

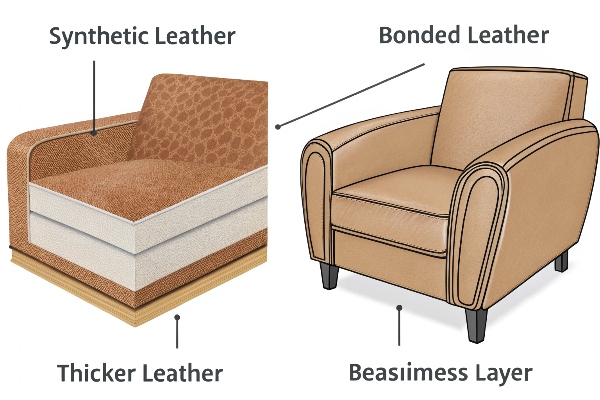

Faux leather is better when you need stable quality, custom colors, or strong tear strength. Bonded leather suits tight budgets that still ask for real leather content, but it flakes sooner and is hard to print.

How do the two materials differ?

| Feature | Faux Leather (PU/PVC) | Bonded Leather |

|---|---|---|

| Composition | 100% synthetic resin on fabric | Shredded leather scraps + PU layer |

| Print Options | Digital, rotary, screen, transfer | Limited, risk of color shift |

| Durability | 3–5 years daily use | 6–18 months under stress |

| Cost per meter | Medium | Low |

| Environmental Claim | Vegan versions available | Uses leather waste but adds more resin |

I once shipped 2,000 meters of faux leather to a hotel chain that first asked for bonded leather. I sent both samples. They ran a quick flex test on their chairs.Bonded leather cracked at 5,000 cycles; the faux piece lasted 25,000. That simple lab report moved the deal and saved them future re-covers. The table above shows why.

Which lasts longer, faux leather or bonded leather?

Your sofa must look fresh for years, not months. Guests will judge wear more than style.

Faux leather lasts longer than bonded leather because its resin layer is thicker and applied in one piece. Bonded leather relies on glue to hold shred, so weak points form and the surface peels first.

Why does bonded leather fail sooner?

| Wear Factor | Faux Leather Response | Bonded Leather Response |

|---|---|---|

| Flexing | Elastic PU bends and rebounds | Mixed fibers break apart |

| Humidity | Stable, closed-cell coating | Moisture weakens adhesive |

| Sunlight | UV stabilizers optional | Topcoat thins fast |

I keep an in-house Martindale machine. When I placed both samples side by side, faux PU still looked smooth at 30,000 rubs. Bonded leather started showing pin cracks at 10,000 rubs. Add foam lamination behind the faux layer and stress spreads even better, so life extends by another 20 %.

Can faux leather be printed on?

A pattern can set your brand apart, yet you fear the ink will rub off.

Yes, faux leather can be printed on by digital UV, sublimation transfer on white PU, or classic rotary techniques. Surface corona or primer helps ink bond, and a matte topcoat seals colors for 50,000 rubs.

Which print process should you pick?

| Method | Best For | Setup Cost | Color Hold |

|---|---|---|---|

| UV Digital | Small runs, photo detail | Low | Very Good |

| Sublimation Transfer | Bright graphics on polyester PU | Medium | Good |

| Rotary Screen | Repeats, high meterage | High | Excellent |

I once printed a flamingo pattern for a kids’ furniture line. We chose UV digital because the order was just 500 meters. The printer finished in two days, and the foam backing kept the sheet flat, so registration stayed tight. Three years later, the chair in my office still shows the bright pink birds.

What are the downsides of faux leather?

No material is perfect. Over-selling PU hurts your rapport with clients when they meet issues later.

Faux leather can trap heat, stretch under heavy load, and may smell of solvents if made poorly. It also needs careful edge folding, or the surface may crack at tight corners.

How can you avoid common problems?

| Downside | Simple Fix I Use |

|---|---|

| Heat build-up | Add perforation punches or mesh backing |

| Stretch/Bagging | Use woven base, not knit |

| Solvent Odor | Ask for water-based PU and GREENGUARD test |

| Edge Cracking | Pre-heat material before tight wrapping |

| Surface Shine Loss | Choose matte topcoat with anti-wear agent |

I learned the edge lesson on a yacht project. We stapled the material cold on a 5 °C day, and micro cracks formed two weeks later. Now I ask crew to warm the rolls with a heat gun before wrapping, and the issue vanished.

Conclusion

Choose printed, foam-bonded faux leather when you need long life, easy branding, and soft feel. Test samples, mind limits, and watch your upholstery last.