Many buyers mix up PU and PVC and end up with products that crack, smell, or fail early. I have seen this confusion cost clients thousands.

PU and PVC are both synthetic plastics, yet they differ in chemical makeup, feel, breathability, weight, and long-term durability; they are not the same and should not be used interchangeably.

You now know they differ, yet the fine points can still feel blurry. Keep reading, and I will break down each key area, add real examples from my daily work, and help you pick the right material with confidence.

Is PU the same as PVC?

Shoppers often think the two labels are marketing tricks. That mistake leads to poor performance and unhappy users.

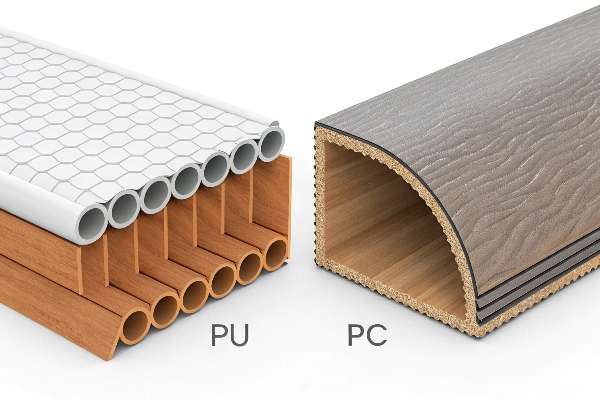

PU is a porous, softer polyurethane coated on fabric; PVC is a denser polyvinyl chloride with added plasticizers. Their structure, touch, and aging behavior differ, so they are not the same.

Chemical and structural makeup

I group the basics into three clear rows:

| Aspect | PU (Polyurethane) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Core resin | Polyol + isocyanate | Vinyl chloride monomer |

| Additives | Fewer plasticizers | Many plasticizers, stabilizers |

| Pores | Micro-porous, airy | Non-porous, sealed |

How that plays out

PU’s micro-pores let water vapor escape. Shoes and seats feel less sweaty. PVC blocks vapor, so it traps heat but repels spills. PU bonds to fabric in liquid form, making it light. PVC uses paste extrusion, making it heavier.

I advise PU for comfort-driven items like fashion bags, furniture backs, and car seats. I pick PVC for rain boots, marine covers, or areas facing strong cleaners. Each option shines when matched to the right job.

Is PVC or PU leather better?

Everyone wants the “best” leather. The answer shifts with the end use.

PU leather is better for softness, breathability, and upscale look; PVC leather wins for low cost, water resistance, and easy cleaning. Your application decides which one rules.

Choosing based on performance goals

Feel and comfort

PU mimics genuine leather grain and stretch. When I design sofas for Nordic clients, they demand that warm hand feel. PVC feels colder and plasticky. Over long sitting hours, PU keeps the user happier.

Cost and lifespan

PVC sheet prices run 15–25 % lower than PU in my sourcing lists. For public bus seats that see rough handling, a replace-every-few-years plan with PVC makes economic sense. PU, when well-formulated, can last longer in indoor settings yet costs more up front.

Environmental view

PU can be water-based or bio-based. My factory now runs a line that cuts solvent VOC by 60 %. PVC relies on chlorine chemistry and plasticizers. Many brands avoid it for green targets. I always check each client’s ESG goals before quoting.

What is the difference between PU and PVC shoes?

Footwear brands risk returns when they pick the wrong upper.

PU shoes feel lighter, breathe better, and resist flex cracking; PVC shoes resist mud, chemicals, and heavy rain but add weight and can crack in cold weather.

Footwear factors that matter

Flex and cold crack

I test samples at –20 °C. PU bends 50,000 cycles with no cracks. PVC often shows white stress lines after 5,000 cycles. Winter boots need that data.

Weight and wearer fatigue

A pair of PU soccer cleats can weigh 40 g less than PVC ones. That small drop helps athletes move faster. Yet fishing boots need PVC’s water block, so weight becomes secondary.

| Property | PU Shoe Upper | PVC Shoe Upper |

|---|---|---|

| Flex life | 50k cycles | 5–10k cycles |

| Cold crack | –20 °C pass | –10 °C fail |

| Weight (men’s 42) | 230 g | 270 g |

| Cost index | 1.3× PVC | 1.0 |

Adhesion and production

PU takes primer and reacts well with water-based glue. PVC needs solvent glue, raising VOC in the workshop. When I audit factories aiming for green certification, switching to PU uppers often cuts their air emission fees.

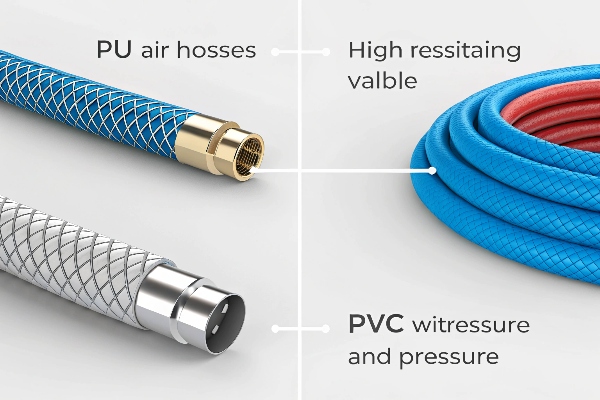

What is the difference between PU and PVC air hose?

Hoses sit under pressure, oil, and UV. A wrong pick can burst mid-shift.

PU air hose offers high pressure, kink resistance, and cold flexibility; PVC hose offers lower cost, chemical resistance, and easy coil memory, but stiffens in cold.

Matching hose to the job

Pressure and recoil

PU has a higher shore hardness yet stays elastic. It handles 150 psi working pressure in my lab tests. PVC handles about 120 psi. PU’s memory lets it recoil back neatly, cutting trip hazards on factory floors.

Temperature window

PU keeps its bend down to –40 °C. That matters in outdoor construction in Canada. PVC starts to stiffen near –10 °C, risking cracks. For tropical indoor use, PVC saves money.

| Feature | PU Hose | PVC Hose |

|---|---|---|

| Working pressure | 150 psi | 120 psi |

| Flex at –20 °C | No kink | Stiff |

| Oil resistance | Good | Fair |

| Price per meter | 1.4× PVC | Base |

Safety and standards

When I supply hoses to food plants, PU passes FDA contact rules after an added liner. PVC grades for that use need special phthalate-free plasticizers, raising cost. Reading the small print on certificates avoids later recalls.

Conclusion

PU and PVC each have clear strengths. Match their traits to your need, and you will save money, boost durability, and keep users happy.