A visit to any factory shows the same puzzle: rolls of plain fabric go in, shiny “leather” rolls come out. I once stared at that change in disbelief.

PVC leather is made by coating a fabric with a paste of poly-vinyl chloride (PVC), plasticizers, and additives, then heating it so the mix fuses into a flexible, leather-like sheet.

Curious minds keep scrolling when they sense that each next line will save them from costly trial and error. Stay with me and I will walk you through every hidden step.

How to make PVC leather?

The first time I helped a client set up a PVC line, we fought foaming, smell, and uneven gloss. Each pain point had one clear root.

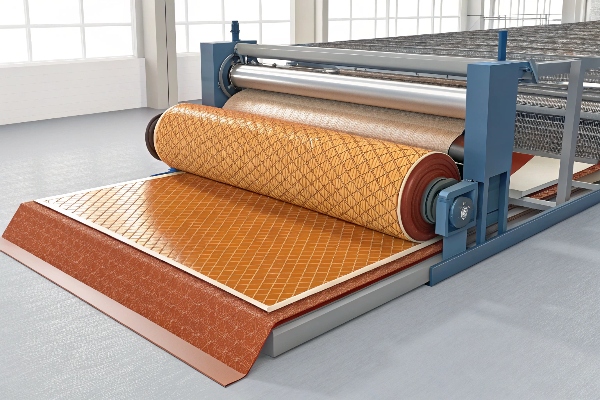

To make PVC leather you spread a PVC plastisol onto a fabric, gel it at 160-180 °C, emboss the warm sheet with a grain, cool it, then trim and roll it. One pass can finish 500 meters in under an hour.

Dive deeper: the six key steps

Step 1: Prepare the base cloth

A strong base gives tear strength. We pick polyester, cotton, or viscose, 70–300 g/m². A light kiss coat of PU adhesive boosts bond strength.

Step 2: Mix the plastisol

The plastisol is liquid at room heat. I keep the mixer at <25 °C so the paste stays flowable.

| Ingredient | Typical parts by weight | Purpose |

|---|---|---|

| PVC resin | 100 | Body |

| Plasticizer (DINP) | 40–60 | Flexibility |

| Stabilizer (Ca/Zn) | 2–3 | Heat hold |

| Filler (CaCO₃) | 10–30 | Cost cut, hardness |

| Pigment | 1–5 | Color |

Step 3: Knife coat the first layer

A knife-over-roll coater spreads 0.2–0.4 mm wet film. Gap control beats bubbles.

Step 4: Gel in hot oven

Time in the oven is short, about 90 seconds. The PVC particles melt and lock to the cloth.

Step 5: Emboss the grain

A steel roller with leather grain presses at 180 °C and 25 bar. Release paper can add shine or matt finish.

Step 6: Cool, inspect, rewind

Fans and chill rolls drop the temp under 40 °C. I mark defects with tape for quick rework.

What is the formulation of PVC leather?

Buyers often think one recipe fits all, yet every end use begs for its own tweak.

A standard PVC leather formula mixes 100 parts PVC resin with 40-60 parts plasticizer, 10-30 parts fillers, about 3 parts stabilizer, plus pigments and 1-2 parts lubricant for smooth release.

Dive deeper: tweak the recipe to fit the job

Why change the plasticizer?

Shoes bend a lot. I shift from DINP to DOTP, adding 5 parts to keep cold crack below −20 °C.

How fillers alter feel

Filler raises hardness but dulls color. I cut CaCO₃ to 5 parts for car dashboards where deep black sells.

| End use | Plasticizer type | Filler (parts) | Special add-on |

|---|---|---|---|

| Sofa covers | DINP 45 | 25 CaCO₃ | Anti-mildew 0.5 |

| Fashion bags | DOTP 55 | 15 CaCO₃ | Pearlescent 3 |

| Auto door | DINCH 50 | 10 CaCO₃ | Low VOC 1 |

Color and UV care

Outdoor seats fade fast. I add 0.3 parts UV absorber and switch to rutile TiO₂ for white goods.

Flame needs

My Gulf clients must meet FMVSS 302. We put in 8 parts melamine polyphosphate. No flame, no fines.

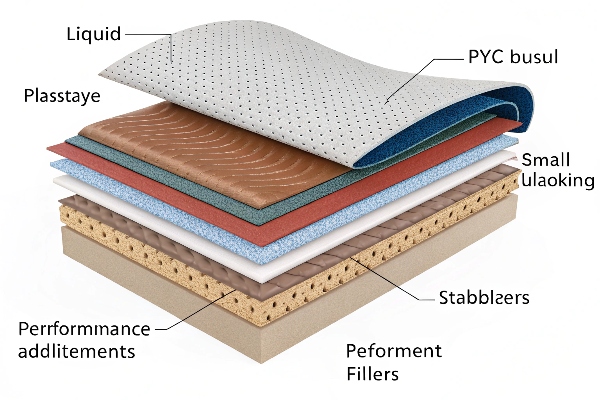

What is PVC leather made of?

Many buyers guess it is only plastic. The truth shows more layers.

PVC leather is built from a textile backing, a liquid PVC plastisol that becomes the skin, and small amounts of plasticizers, stabilizers, pigments, fillers, and performance additives.

Dive deeper: the anatomy layer by layer

Layer 1: Textile backing

I choose knit for stretch shoes, woven for tough luggage. Denier and weave decide tear and seam strength.

Layer 2: Adhesive tie coat

A thin PU or acrylic film bonds the plastisol to the cloth. It adds 5 g/m² weight yet doubles peel strength.

Layer 3: PVC skin

This 0.25–1.0 mm layer gives color, touch, and most of the thickness. Its recipe controls softness and gloss.

| Layer | Thickness (mm) | Main role | Key test |

|---|---|---|---|

| Backing cloth | 0.2–0.5 | Strength | Tear (N) |

| Tie coat | 0.01 | Bond | Peel (N/cm) |

| PVC skin | 0.25–1.0 | Feel, look | Martindale (cycles) |

| Top coat | 0.005–0.02 | Scratch guard | Taber (mg loss) |

Layer 4: Top coat or finish

I spray a PU top coat with matting wax. It cuts sticky feel in humid rooms and wins higher hydrolysis hours.

Additive pocket

Inside the skin we hide fungicides, UV blockers, and fragrance beads if a brand likes new-car smell.

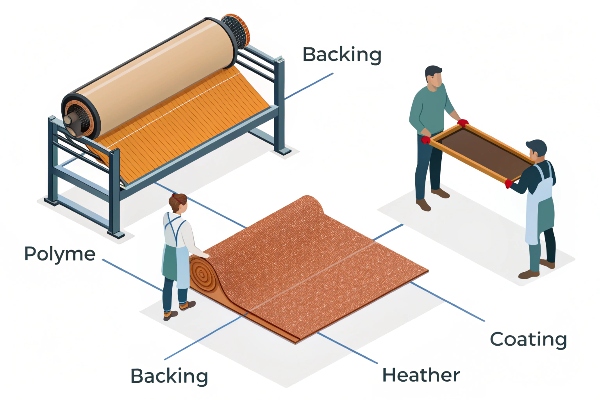

What is the process of making faux leather?

Friends often ask if PU, PVC, and microfiber follow one line. The answer saves them wasted R&D.

Making faux leather starts with choosing a backing, coating or laminating it with a polymer (PVC, PU, or solvent-free), gelling or curing the layer under heat, embossing, finishing, and rolling. The core steps stay the same; the chemistry changes.

Dive deeper: compare PVC with other faux leathers

PVC vs. PU: heat vs. cure

PVC gels by melting. PU cures by solvent flash-off or water reaction. PVC ovens run 180 °C, PU dryers often stay below 120 °C.

| Feature | PVC leather | Solvent PU | Water-borne PU | Microfiber PU |

|---|---|---|---|---|

| Cost index | 1.0 | 1.5 | 1.8 | 2.0 |

| Softness | Medium | Soft | Very soft | Very soft |

| VOC emission | Low with Ca/Zn | High unless recycled | Very low | Very low |

| Hydrolysis | 2-3 years | 3-5 years | 5-7 years | 7+ years |

| Recyclability | Difficult | Hard | Better | Better |

Energy and carbon

PVC lines pull more power due to high oven heat, yet PU needs solvent recovery. I run a Life Cycle check for clients to pick the greenest path.

End use guide

PVC rules mass furniture. Solvent PU leads in fashion. Water-borne PU wins in kids’ toys. Microfiber hits high-end cars.

Conclusion

PVC leather forms when a PVC plastisol bonds to fabric, then gels, embosses, and cools. The recipe, layers, and heat steps decide cost, look, and life.