Many buyers worry whether their final customized microfiber leather will match the original sample, especially for automotive seats that require strict accuracy.

Our custom process ensures stable texture, strong structure, and color accuracy close to 98% so clients get reliable final products that match their expectations.

I follow each project step by step because every detail matters when we develop 1.2mm microfiber leather for automotive seats.

Key Factors That Determine the Quality of Custom Microfiber Leather: Texture, Strength, Color Accuracy, and Durability?

Buyers often struggle to judge quality from appearance alone, yet small differences decide long-term performance.

Texture and strength come from the microfiber base, while color accuracy and durability depend on coating quality and stable production control.

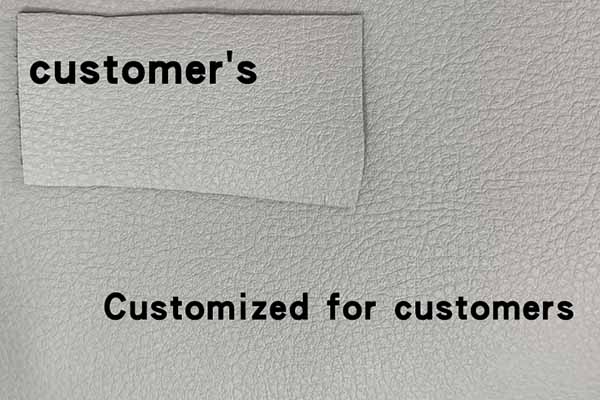

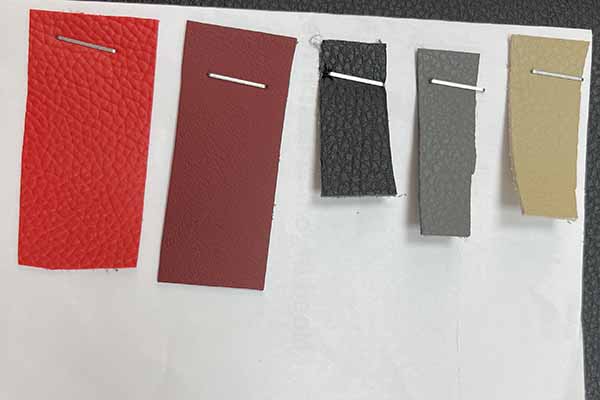

In many projects, clients send us their own samples. I remember receiving the sample from this project, and the customer asked for a 1.2mm thickness for automotive seats. They wanted the final color to match 98% of the original sample and the grain to stay exactly the same. This requirement is common in the automotive industry because seat covers must look consistent under different lighting conditions.

To reach this level, we start with fiber density control. A stable microfiber base gives strength and prevents deformation during coating and embossing. The coating layer controls color accuracy. We test small patches under sunlight and indoor lights to ensure the color does not shift.

Durability comes from abrasion resistance, hydrolysis resistance, and tear strength. For 1.2mm automotive leather, I always suggest a strong base layer so the material resists long-term stretching. Below is a clear breakdown:

| Quality Factor | What It Affects | Why It Matters |

|---|---|---|

| Texture | Surface grain | Ensures visual match to sample |

| Strength | Tear and pull resistance | Important for car seats |

| Color accuracy | Visual consistency | Must match sample close to 98% |

| Durability | Long-term use | Prevents wear and cracking |

How Advanced Testing and Quality Control Ensure Consistency in Customized Microfiber Leather Production?

Clients often worry about color deviation or grain mismatch when ordering bulk quantities.

Stable testing and repeated inspections prevent quality drops and keep every batch aligned with the approved sample.

During production, we run each color batch through strict checking. I always ask the team to compare the coated sheets with the client’s sample under multiple lights. Automotive customers often test with daylight, fluorescent light, and warm white light because seat colors must stay consistent across environments.

We also test thickness with digital gauges to ensure that each roll stays close to 1.2mm. The grain must align with the sample, so we adjust our embossing pressure until the pattern matches. I still remember the exact moment we compared the first finished bulk sample with the client-provided piece. The color was almost identical, and the texture felt the same. We reached the 98% color match target on the first trial.

Below is how we keep everything stable:

| Control Process | Purpose | Result |

|---|---|---|

| Color lightbox test | Check color under different lights | Prevent visible color shifts |

| Thickness control | Keep 1.2mm stable | Keep automotive seat performance stable |

| Embossing adjustment | Match sample grain | Achieve texture consistency |

| Final sample match | Confirm before mass production | Reduce risks for clients |

The Advantages of Working With a Professional Microfiber Leather Manufacturer for Custom Projects?

Many buyers worry that customization will take too long or fail to match the reference sample.

Working with a professional team shortens the process and ensures stable matching from sample to bulk order.

When clients send their own samples, we guide them through each step. We confirm grain, thickness, base strength, and coating type. Because of our experience with automotive customers, we know how to manage strict color targets and grain consistency. For this project, we produced two large sample sheets and sent them to the customer. They compared our samples with their original pieces and confirmed the match.

Clients choose to work with us because we provide fast sampling, stable mass production, and direct factory pricing. We also help customers reduce risks by checking every detail before bulk production starts.

Here is a simple summary of the main advantages:

| Advantage | Benefit to Client |

|---|---|

| Fast sample development | Speed up project launch |

| Professional color matching | Reach up to 98% similarity |

| Accurate texture reproduction | Keep grain identical |

| Direct factory control | Lower cost and better stability |

| Automotive-grade quality | Long service life and high consistency |

Conclusion

We match color, texture, and strength from sample to final bulk so clients receive stable and reliable custom microfiber leather.